300 +

余项专利

300 +

多人的研发技术团队

1000 万

每年研发费用投入

About us

300 +

余项专利

300 +

多人的研发技术团队

1000 万

每年研发费用投入

solution

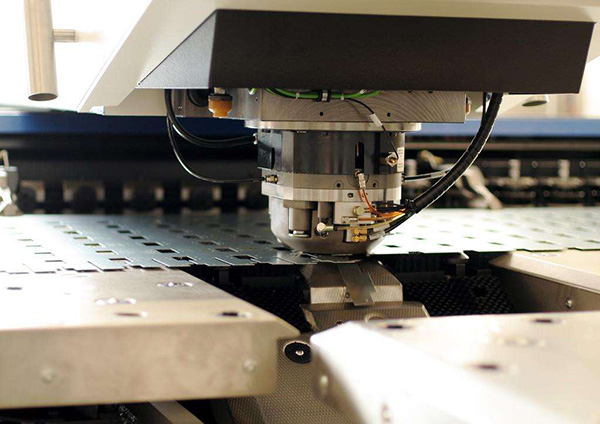

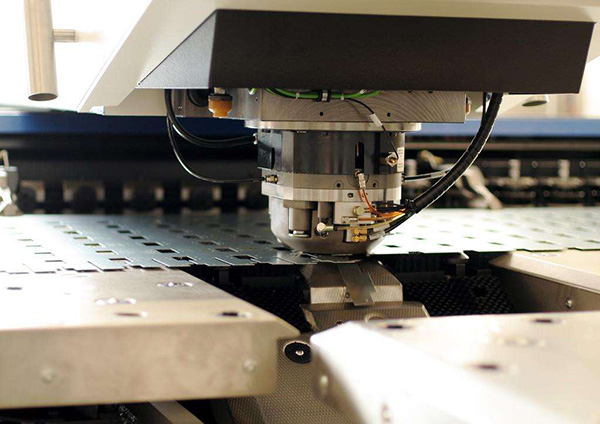

随着对汽⻋安全⽅⾯的法律法规的硬性要求的出台,汽⻋及零部件的身份的唯⼀性提出了很⾼的要求,汽⻋及零部件的身份的确⽴,是实现产品质量追溯及召回的基础。 激光加⼯技术是⼴泛应⽤于汽⻋⽣产的先进技术,多年来已应⽤于制造⾼品质的汽⻋配件以及标贴。 激光雕刻,激光蚀刻技术,激光焊接以及激光切割机,⼴泛应⽤于汽⻋⼯业.

激光加⼯技术是⼴泛应⽤于汽⻋⽣产的先进技术,多年来已应⽤于制造⾼品质的汽⻋配件以及标贴。 激光雕刻,激光蚀刻技术,激光焊接以及激光切割机,⼴泛应⽤于汽⻋⼯业.

传统焊接对焊接的技巧和焊剂的成本要求过⼤,会提⾼⽣产所需的成本。⽽且焊后还要进⾏加⼯的步骤,时间效率⾮常缓慢。正因为有了这些缺陷的存在,激光焊接机将更好的服务于汽⻋制造在内的诸多⼯业制造领域中

在造船过程中,切割与焊接工时占到整个船体建造的40%以上,相关费用占整个船体造价的40%-50%,其质量的好坏直接影响到船体的整个质量。铭镭激光凭借先进的切焊技术已成为国内外大型船厂的共同选择。

“精密制造”,已经成为当下制造业的一致追求。对于汽车制造、轨道交通制造、航空航天制造、造船业等等企业来说,精密制造尤为重要。其中造船业,其主要原材料为钢,因而对原材料钢的加工要求,无论从精度上、速度上、产能上都有较高的要求。随着激光切割技术的兴起,激光切割机开始广泛应用于造船业。

激光切割技术带给造船业的是高效率高精度的金属加工、超短的生产周期以及较低的生产成本。激光切割技术一次成型,割缝质量好,切口面垂直性好,无挂渣,氧化层薄,表面光滑,无需人工二次加工,可直接焊接,且热变形小,曲线切割精度高,材料利用率高,这为造船业的装置质量提供了保障,从而减少装配的工作量、装配周期、材料与人工成本浪费。

我国工程机械行业在2016年三季度以来持续回暖,主要原因在于:下游固定资产投资增长、前一年销量低基数效应、国三标准强制实施。工程机械行业经过四年多的行业调整,设备开工小时数、毛利率、负债率等指标基本已经稳定,盈利能力开始恢复,整体板块调整基本结束,在良好的销量数据以及海外政策利好的刺激下,行业价值重心逐步抬升。

与此同时,机械的自然淘汰周期也让行业缓慢复苏,从2008年设备销售高峰至今,大量设备需要更新换代,另外随着“一带一路”的加速推进,工程机械行业将迎来新的发展机遇。

机箱电柜行业在近几年的发展革新有目共睹,从方方正正古板的外观到如今新潮亮丽的炫酷外观,再到各种个性化的机箱外观,可以看出设计师们都花了不少心思。

由于日益激烈的竞争,机箱电柜行业多品种小批量的产品越来越多,已从以往大批量、设计单一、长制作周期逐步转至小批量、多种类、敏捷加工,机箱电柜厂家不得不进行加工方式改革。

同时随着机柜需求量的增加,对机柜加工工艺的质量也提出了更高要求。在机柜制造过程中,传统的机械加工工艺易造成切割边缘泛起锐口、毛边、毛刺等现象,影响成品美观,光纤激光切割机则能很好地避免这些弊端。

中国逐渐成为国际加工制造中心,金属加工的需求不断加大,而金属加工行业中的电器控制箱、机器外壳等一般来说都是钣金件,所以钣金加工能力需求也不断提高.

随之,工艺的复杂性也比较高,甚至有些零件工序达到几十道之多,也在精度方面对钣金加工提出了更高的要求。

传统的钣金加工有剪板、冲裁和折弯等工艺流程,其中冲裁工艺流程需要大量的模具,浪费大量的时间成本和资金成本。

激光切割是一种高效、高质的柔性加工工艺,激光钣金加工无需模具,相较于传统加工手段,操作简单,更加灵活,且运行维护成本更低。

21世纪初,随着国内激光切割机生产企业的出现,国内第一台高功率光纤激光切割机切割机的问世,使得激光切割机只能依赖进口的局面被打破,同时使得昂贵的电梯价格也大幅下降。

先进光纤激光切割机的运用,提升了国内电梯制造的品质,各电梯厂商也意识到提高设备自动化、智能化程度,才能灵活自如应对各项生产任务,提升产能。

电梯行业内不锈钢板、带膜材料比较多,对断面的光洁度要求比较高。激光切割和传统的数控冲床相比具有表面光洁度高、不存在接刀口、不存在模具损耗等优势。光纤激光切割机还能切割更细更小的尖角,能有效避免冲床冲压过程工件产生的塑形变形,提升产品的核心竞争力。在厚度6mm以下板材的切割上,光纤激光切割机也独具速度优势,例如1mm厚不锈钢切割可以实现直线速度60m/min,有效提升企业产能。

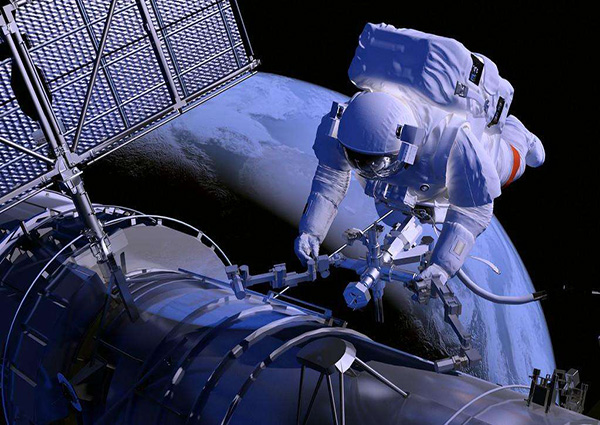

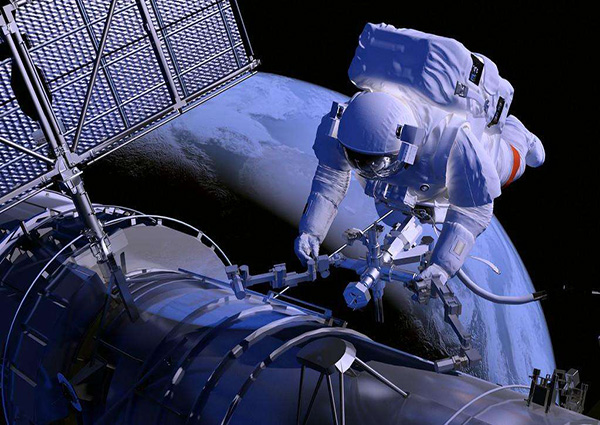

激光制造技术在国防和航空航天领域的产业化应用前景远大,具有效率高、能耗低、流程短、性能好、数字化、智能化的特点。针对现状,我国将继续发挥激光制造技术的优势,改变我国航空航天领域关键器件和技术主要依赖进口的现状,最终形成我国新一代激光制造产业链。

铭镭激光把激光焊接技术与航空制造技术相融合,作为一项成熟的技术成为航空用轻质合金连接的一种重要手段,对现代航空制造中结构件、部分发动机部件间的连接,起着举足轻重的作用。

门把手行业是家居行业的重要组成部分,也是激光制造的基础和重要支撑,门把手主要分为管型把手、家用把手、门窗把手,其中这三种类型的门把手都需要用到门把手焊接。

激光焊接机是利用高能量的激光脉冲对材料进行微小区域内的局部加热,激光辐射的能量通过热传导向材料的内部扩散,将材料熔化后形成特定熔池。它是一种新型的焊接方式,主要针对薄壁材料、精密零件的焊接,可实现点焊、对接焊、叠焊、密封焊等,深宽比高,焊缝宽度小,热影响区小、变形小,焊接速度快,焊缝平整、美观,焊后无需处理或只需简单处理,焊缝质量高,无气孔,可精确控制,聚焦光点小,定位精度高,易实现自动化。