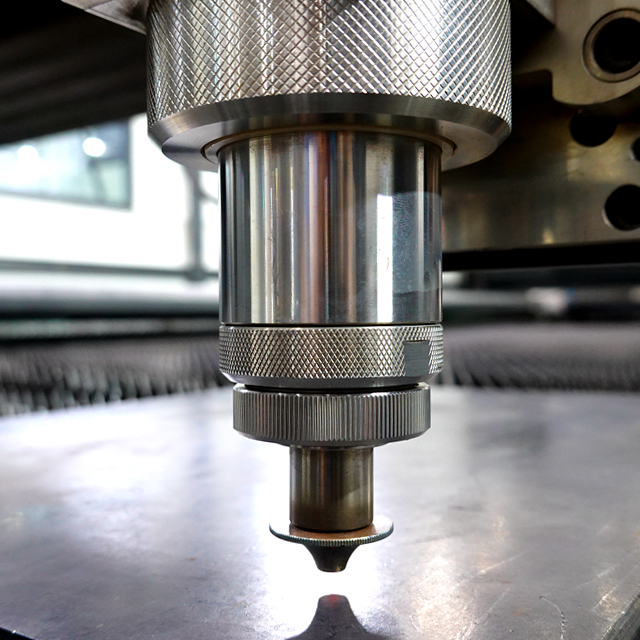

1. Stepless perforation greatly reduces the perforation time by about 75% and improves the processing efficiency;

2. Continuous perforation, high stability, the waste hole rate is reduced from about 5% to 0.2%, improves the integrity of the workpiece;

3. High accuracy rate, less slag accumulation, stable follow-up, stable start cutting point, ensuring the best cutting section;

4. Reduce perforation time, save gas, reduce power consumption, reduce the risk of damage to lasers and cutting heads, and

improve material utilization;

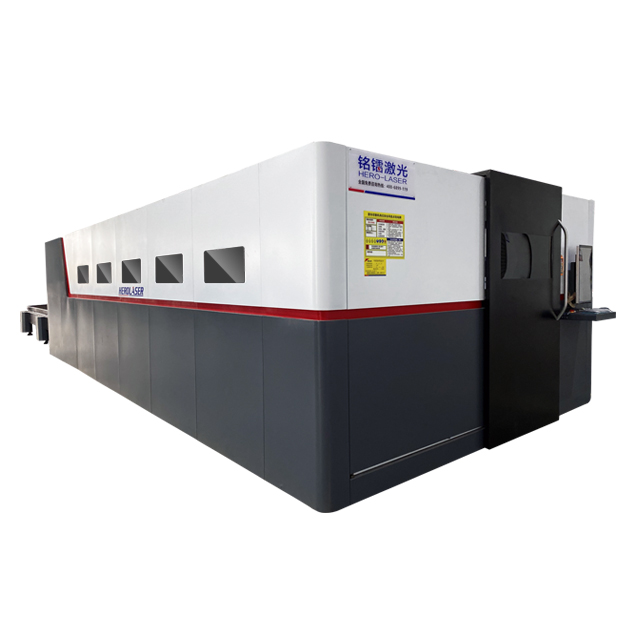

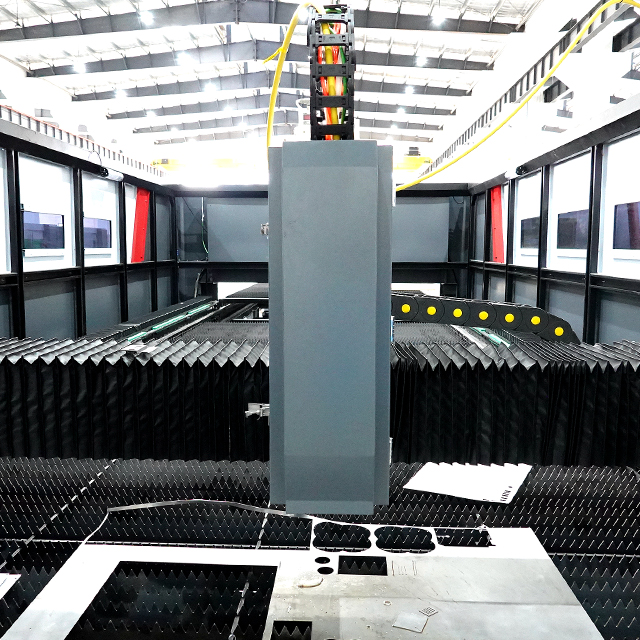

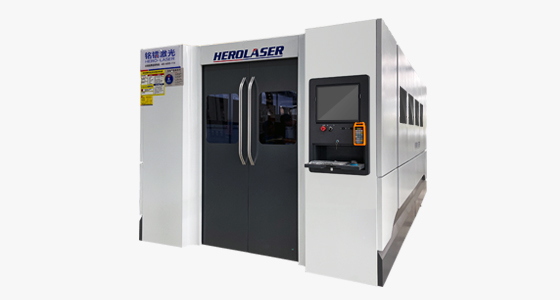

ML-CF-6025FB series laser cutter is a fiber laser cutting machine with advanced structure design and excellent machine tool performance, which applies the world-class CNC and fiber laser. It adopts gantry-type double-drive structure ,integral welded base and rack so that vibration aging treatment is carried out to eliminate the stress during welding and processing after rough machining ;and pinion transmission structure with fast speed, high precision, one-time cutting and forming without subsequent processing.